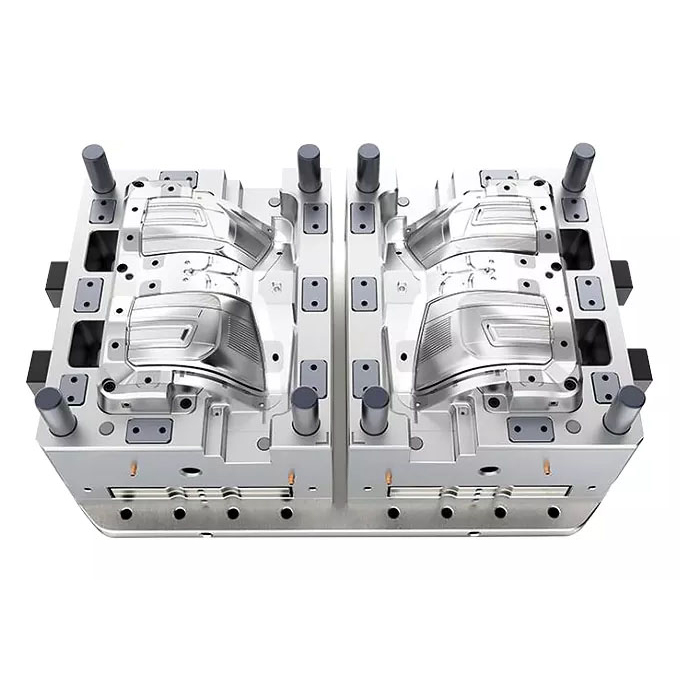

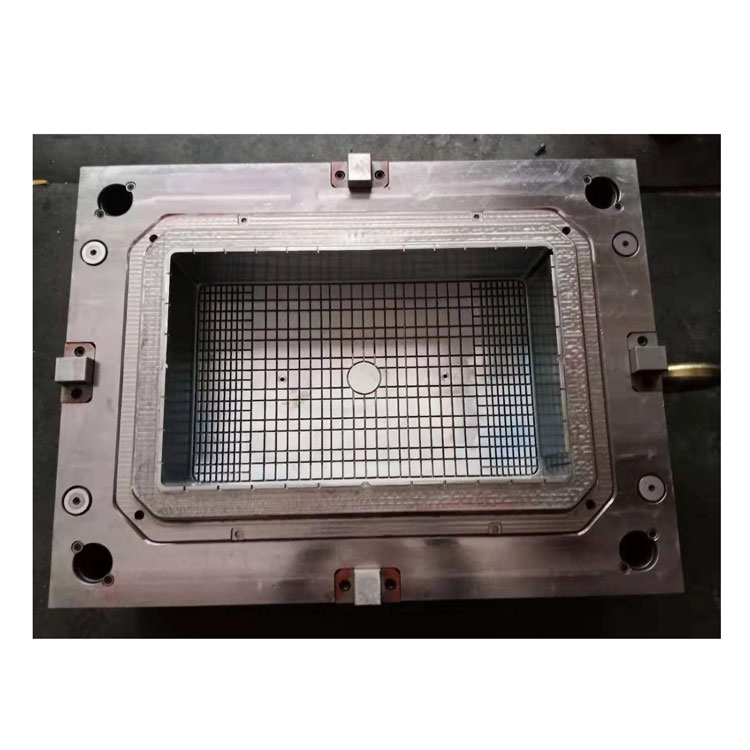

Injection Molding Tooling

Plastic Injection molding is a common production process used to manufacture plastic parts from materials called thermoplastics. This process is typically used to produce plastic parts in large quantities. Plastic Injection Molding involves melting plastic and then injecting it into a mold, where it cools and solidifies, taking the final form as the desired plastic part.

This process can be repeated as required to produce thousands or even millions of the same part. Hence, the process of plastic injection molding allows manufacturers to create as many plastic parts as they want using just a single mold.

Why Choose Us

High Quality

Although we offer highly economical rates, we never compromise on the quality of our products and services. Our process quality systems ensure that your parts are of the highest quality possible for your application.

Quick Turnaround

Our team members are experts when it comes to delivering products with speed and excellence. With a quicker turnaround, we help you reach the market quicker and give you an edge over your competitors.

Online Quotes

Our interactive online quotation system provides fast online quotes for plastic injection molding so that the manufacturing process can commence sooner.

Custom Design Optimization

Our plastic injection molding machines cover a wide range of capacities horizontally and vertically, which allows us to provide virtually any short or long-run custom design production you require.

How To Work With Us

Submit your free quote request with a description and technical drawing of your product. In case of no technical drawing, no worries. We can reverse engineer.

We usually get back to you within 24 hours.

Once you approve the quote and make the deposit, we start working on the initial work of mold-making, preparing machines, and so on.

Packaged, labeled, and shipped to your door right on time.